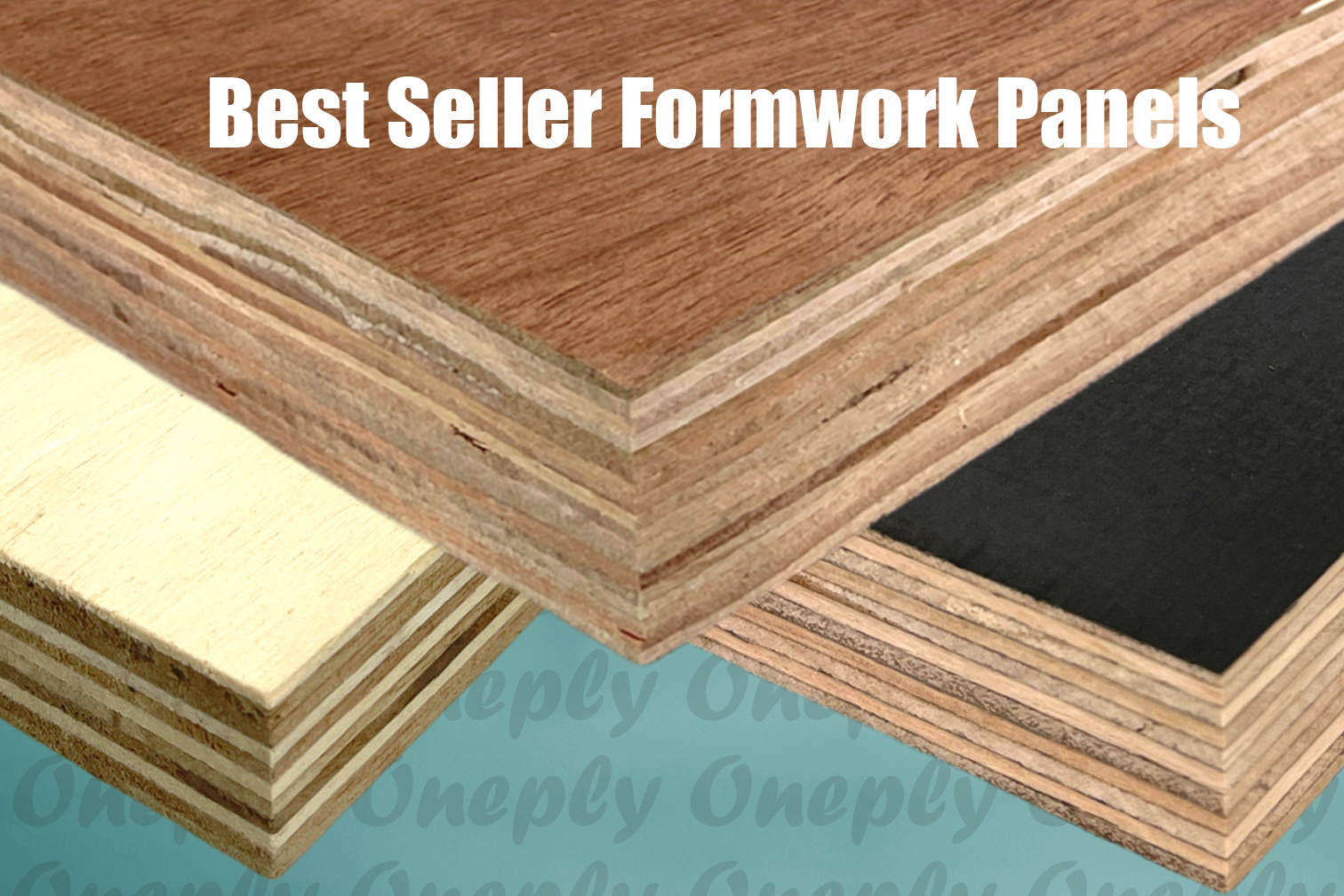

When considering the right plywood for your construction project, especially for concrete forming to produce glossy surface concrete, it's essential to understand the differences and applications of MDO, HDO, and Phenolic (Film Faced) plywood. Each type offers unique properties suitable for various construction needs, as reflected in Oneply Online Shop's diverse offerings.

MDO Plywood

MDO (Medium Density Overlay) Plywood is celebrated for its durability and smooth finish, thanks to a medium-density fiber overlay. This makes it ideal for projects requiring a high-quality finish that's also paint-ready. MDO's resilience against weather and its smooth surface are its hallmarks. Oneply offers options like the MDO 1S Panel, MDO 1SF Panel with Film Backer, and variants with high-density and purple color for specific requirements .

HDO Plywood

HDO (High Density Overlay) Plywood takes the qualities of MDO a step further, with a denser overlay that provides even greater durability and resistance to moisture. This type is particularly suited for demanding environments where the plywood will be exposed to harsh conditions. HDO variants at Oneply include Basic 2S Formply, Premium 2S Formply, and Premium HD 2S Formply, among others, catering to a wide range of construction needs.

Phenolic (Film Faced) Plywood

Phenolic Plywood, also known as Film Faced Plywood, is designed specifically for use in concrete formwork, offering a glossy finish to concrete surfaces. The phenolic film coating ensures water resistance and durability, making it a go-to choice for projects requiring repeated use and exposure to moisture. Oneply's selection, including Form Basic and Pro Form, is tailored for concrete forming applications, highlighting the plywood's robustness and ability to produce sleek, glossy concrete finishes.

Comparing the Types

- Surface Finish and Durability: While all three types are durable, HDO and Phenolic Plywood offer higher resistance to moisture and wear, making them more suited for outdoor or high-moisture environments. MDO provides a smooth finish but with slightly less resistance compared to HDO.

- Application Specificity: MDO is versatile for a variety of applications, including painting and architectural uses. HDO is preferred for more demanding conditions where durability is key. Phenolic Plywood is the best choice for concrete formwork, especially when a glossy finish is desired on the concrete surfaces.

When selecting the plywood type for your project, consider the specific conditions it will face and the finish you desire. Oneply Online Shop offers a range of options in each category, providing the flexibility to choose the best material for your construction needs, with detailed product descriptions and specifications to guide your selection process .