Frequently Asked Questions

1. What is concrete formwork?

2. What are the types of concrete formwork?

3. Why is high density plywood important in concrete formwork?

4. How does concrete formwork benefit construction projects?

5. What factors should be considered when choosing formwork?

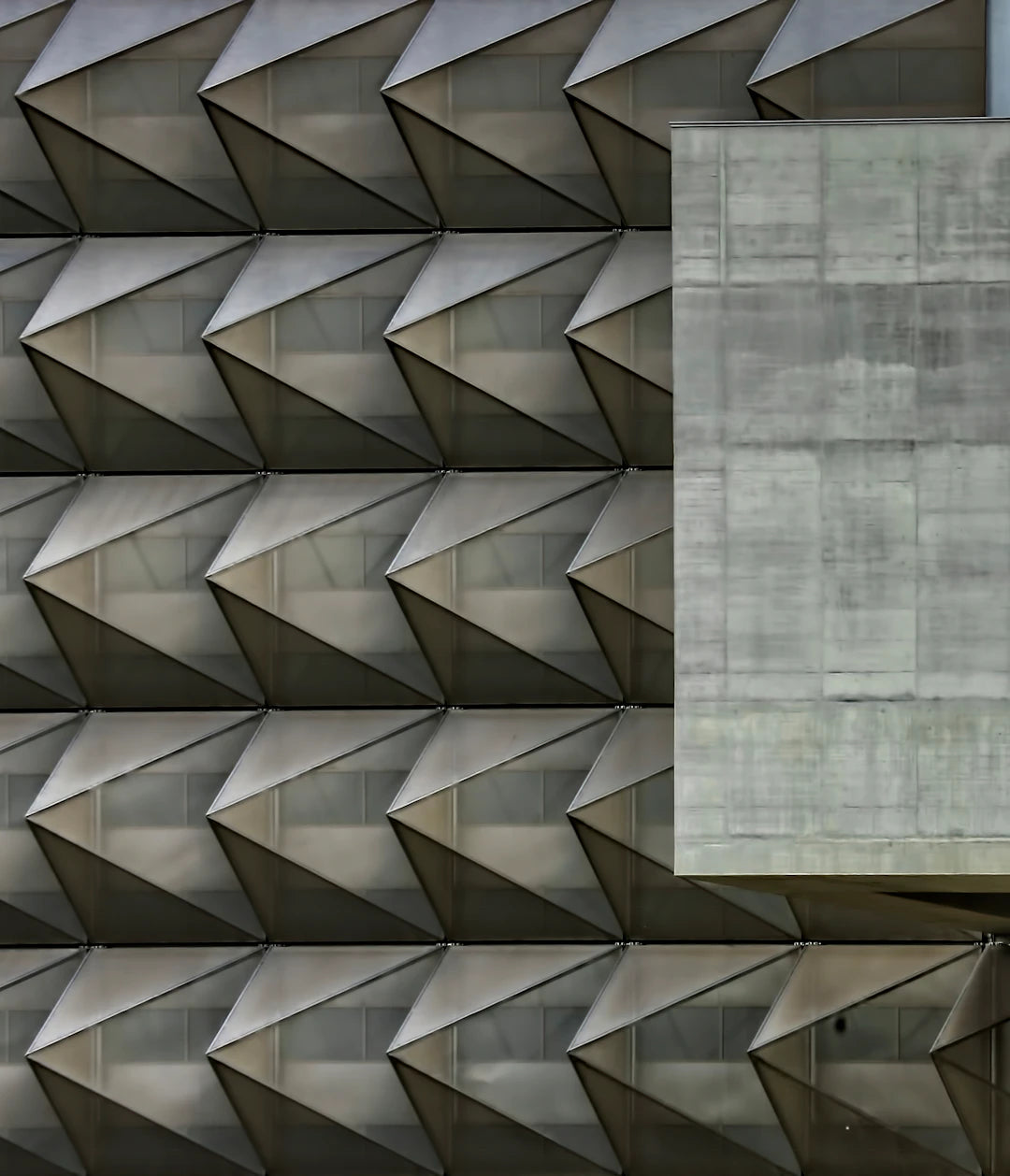

Concrete is a pillar in the construction industry due to its durability, strength, and versatility. One of the critical aspects of working with concrete is understanding the methods of formwork used to shape and mold this essential material. The use of concrete formwork not only impacts the final aesthetic but also affects the efficiency of the construction process. This article delves into the various styles of construction that utilize concrete formwork, emphasizing the role of high density plywood and concrete form ply.

Understanding Concrete Formwork

Concrete formwork refers to the molds and structures that are used to hold fresh concrete in shape until it has sufficiently cured. This process is vital in creating uniformly shaped concrete components, including walls, slabs, and columns. Formwork can be temporary or permanent, and its design can considerably influence the structural integrity and aesthetic appeal of the finished product.

Types of Concrete Formwork

Various types of concrete formwork exist to suit different styles and requirements of construction. Each formwork type has its advantages and specific applications. Let’s explore some common types that are widely used in construction:

Traditional Timber Formwork

Timber is a widely recognized material traditionally used for formwork. It is easily available, cost-effective, and can be custom-made to fit various shapes and dimensions. However, timber formwork is often prone to warping and may require more labor to assemble and dismantle. For improved outcomes, many contractors opt for high density plywood, which provides durability and strength while minimizing the risk of deformation during the concrete pouring process.

Steel Formwork

Steel formwork is a robust, highly durable option that can be used for large-scale construction projects. They are reusable, making them an environmentally friendly selection for builders, as they minimize waste. Its smooth surface facilitates quick stripping and aids in creating a fine finish on the concrete surface. Steel formwork is exceptionally beneficial for projects requiring consistent dimensions and high-quality output.

Plastic Formwork

Plastic formwork has gained attention due to its lightweight properties and ease of handling. It is particularly favored for small projects and can be easily assembled, making it a popular choice among DIY enthusiasts. Its versatility allows it to be employed in various applications, from wall construction to decorative features.

Insulated Concrete Formwork (ICF)

Insulated concrete formwork integrates the structural features of traditional formwork with insulation properties. Composed of interlocking panels, ICF minimizes thermal bridging, providing energy efficiency to the finished structure. Suitable for residential buildings, ICF offers good noise reduction and maintains comfortable temperatures inside.

Specific Applications of Concrete Formwork

Concrete formwork serves multiple purposes in different construction styles and techniques. Understanding these applications offers better insight into how formwork can be effectively utilized in specific projects.

Residential Construction

Residential buildings frequently rely on concrete formwork to create reliable walls, foundations, and driveways. High density plywood is particularly valuable for forming walls, as it can withstand the pressure of wet concrete while providing a smooth surface finish. The flexible nature of plywood allows for unique architectural designs that add character to homes.

Commercial Structures

In commercial construction, the timely delivery of high-quality concrete structures is crucial. Utilizing concrete form ply helps achieve this goal by providing a consistent surface finish. The construction of multi-story buildings often employs large-scale formwork systems that enable quick assembly and disassembly, optimizing the workflow and minimizing downtime.

Infrastructure Projects

Infrastructure projects, such as bridges and tunnels, heavily rely on concrete formwork for their structural components. The robust nature of steel formwork is especially advantageous, as it can endure the demands of heavy lifting and exposure to harsh environmental conditions. Here, the ability to create precise shapes and maintain dimensional accuracy is paramount for safety and structural integrity.

Benefits of Using Concrete Formwork

Implementing effective concrete formwork comes with numerous benefits that enhance the overall quality of construction projects. Below are some notable advantages:

- Cost Efficiency: Proper formwork can help prevent material wastage and reduce labor costs, leading to better financial outcomes in construction.

- Speed of Construction: Efficient formwork systems lead to faster project timelines by expediting the pouring and curing process, empowering contractors to meet tight deadlines.

- High-Quality Results: Utilizing high density plywood and other engineered formwork materials can minimize surface defects and ensure a superior finish.

- Flexibility and Customizability: With flexible options like timber and plastic, contractors can easily tailor formwork to meet specific design requirements.

- Improved Safety: Advanced formwork techniques enhance site safety by providing secure structures that prevent accidental collapses during concrete pouring.

Factors to Consider When Choosing Formwork

When selecting a concrete formwork system, several factors need to be evaluated to ensure the best results:

Project Scale

The size and complexity of the project will significantly impact the formwork choice. Smaller projects may benefit from lightweight plastic or timber forms, while large-scale commercial or infrastructure projects might require robust steel systems.

Budget Constraints

Designing a budget is essential in determining which formwork materials to use. High density plywood, for instance, may have a higher initial cost but offers durability and reuse benefits that can save money in the long run.

Construction Schedule

The timeline for project completion often dictates the chosen formwork system. Systems that offer quick assembly and disassembly will be more advantageous when working on tight schedules.

Aesthetic Qualities

Different formwork materials can yield diverse aesthetic outcomes. If the finish of the concrete is a priority, high quality concrete form ply may be preferred for its smooth finish and ability to minimize defects.

The Future of Concrete Formwork

As technology advances, new trends are revolutionizing formwork design and application in the construction industry. Innovations such as 3D-printed formwork, which allows for unique geometric shapes, are making waves in construction efficiency and creativity. Moreover, sustainability remains a pressing concern. As builders strive for greener practices, the development of eco-friendly formwork materials that minimize environmental impact will likely gain traction.

Final Thoughts: Constructing the Path Ahead

The role of concrete formwork in construction is undeniable. Its influence stretches across various project types and styles, ensuring that designers and builders can bring their visions to life. Whether you are fabricating a unique residential space or erecting a robust commercial structure, having the right formwork is invaluable. By understanding the different types of concrete formwork and their specific applications, alongside the advantages of high density plywood and concrete form ply, you can enhance the effectiveness and quality of your construction projects. Embrace the journey of formwork innovation, and watch your constructions stand the test of time.