Overview

Choosing the right formwork plywood is essential for construction projects, impacting durability and cost-efficiency. Factors influencing lifespan include plywood quality, usage type, environmental conditions, and maintenance practices. Moisture resistant and film faced plywood are recommended for longevity. Regular inspections and careful handling can maximize lifespan. Replace plywood showing visible damage or reduced structural integrity to ensure safety and effectiveness. Future trends suggest a move toward eco-friendly and smart plywood options.

Frequently Asked Questions

1. What is formwork plywood used for?

2. What are the main types of formwork plywood?

3. How can I extend the lifespan of formwork plywood?

4. What factors affect the lifespan of formwork plywood?

5. When should I replace my formwork plywood?

When undertaking a construction project, one often overlooks the importance of choosing the right materials. Among those materials, formwork plywood plays a crucial role, especially in generating concrete structures. It is essential to understand the lifespan of this material to make informed decisions regarding your project. In this blog, we will delve into the factors influencing the lifespan of formwork plywood, its types, maintenance tips, and expected longevity.

Understanding Formwork Plywood

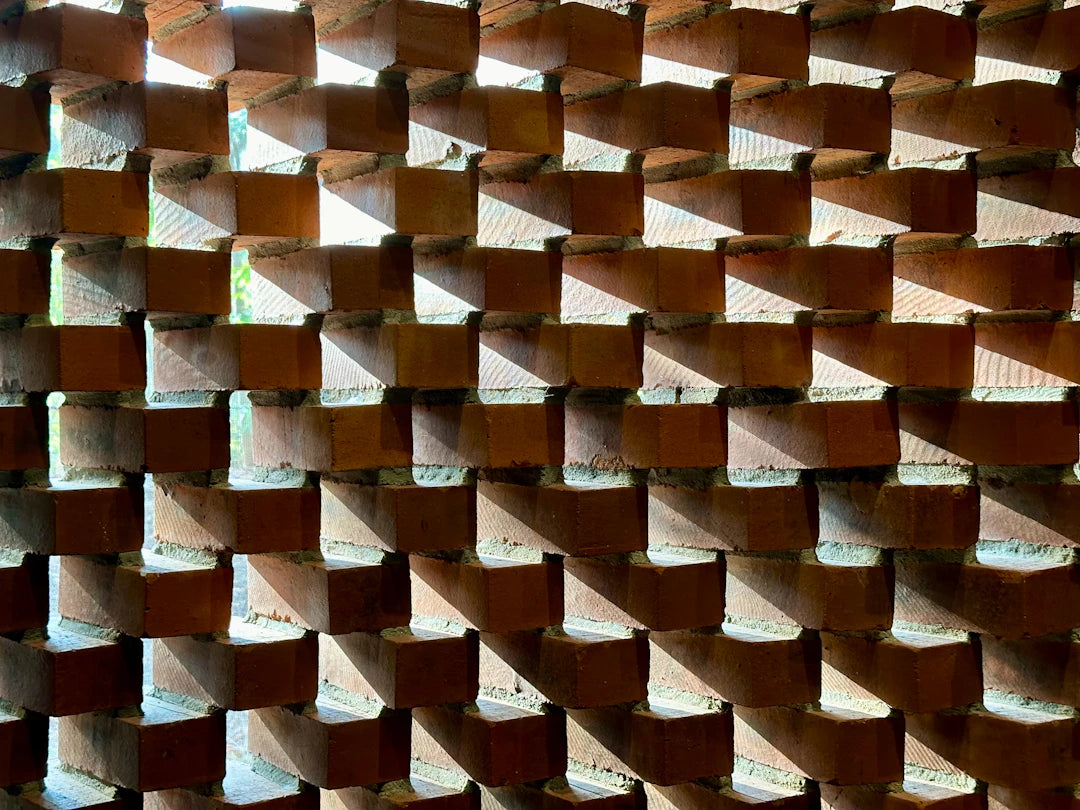

Formwork plywood is a specific type of plywood designed to withstand the stresses of concrete pouring and shaping. This plywood is primarily used in construction for creating temporary structures, providing a mold for concrete until it hardens and retains its shape. Two primary types of formwork plywood include:

- Moisture Resistant Plywood: This type of plywood is treated with waterproof adhesives that prevent moisture infiltration. It's particularly suited for construction projects exposed to wet environments.

- Film Faced Plywood: This is a high-quality plywood coated with a film, making it impervious to water and enhancing its durability. Film faced plywood is often more reusable than standard plywood, as the surface offers resistance to damage and sticking.

What Affects the Lifespan of Plywood?

The lifespan of formwork plywood can vary significantly based on several factors, including:

1. Quality of the Plywood

A higher quality plywood, such as moisture resistant plywood and film faced plywood, will inherently have a longer lifespan. Plywood manufactured under stringent standards and using high-grade materials will be more durable and capable of resisting environmental stresses.

2. Type of Use

How formwork plywood is utilized plays a significant role in its longevity. If it’s used in high-stress applications consistently, it may wear down faster. Conversely, lighter use may extend its lifespan. Additionally, the specific type of project—commercial versus residential—can affect overall wear and tear.

3. Environmental Conditions

External conditions have a direct impact on the durability of formwork plywood. If it is subjected to extreme weather conditions like heavy rain, high humidity, or cold temperatures, the lifespan will likely be reduced. For instance, moisture resistant plywood is engineered to endure these conditions better than standard plywood.

4. Maintenance Practices

Proper maintenance can significantly extend the lifespan of formwork plywood. Regular inspections and careful handling can minimize damage. When the plywood is not in use, storing it in a dry and well-ventilated area helps prevent issues related to moisture absorption or severe climate exposure.

Expected Lifespan of Formwork Plywood

The expected lifespan of formwork plywood depends heavily on the factors mentioned above. Generally, for quality materials like moisture resistant plywood and film faced plywood, here are some expected lifespans based on their usage:

- Continuous Use: In continuous use scenarios, film faced plywood can last anywhere from 15 to 30 days of concrete pouring, depending on its maintenance and environmental exposure.

- Seasonal Use: If plywood is only used seasonally, its lifespan can extend significantly—up to several years—provided it is properly stored when not in use.

- Extreme Conditions: In cases of poor protection and extreme weather conditions, even high-quality plywood can perish after just a few uses. This emphasizes the importance of using moisture resistant plywood in climates prone to wet conditions.

Maximizing the Lifespan of Formwork Plywood

To ensure that formwork plywood reaches its potential lifespan, consider implementing these strategies:

1. Select the Right Type

Choosing between moisture resistant plywood and film faced plywood should align with the specific requirements of your project. For wet conditions or repeated use, film faced plywood is often the best choice due to its robust durability.

2. Careful Handling

Improper handling can lead to chips and cracks, diminishing the lifespan of your plywood. Train your labor force on careful handling practices to avoid damaging the edges or surfaces.

3. Conduct Regular Maintenance

- Inspection: Regularly inspect the plywood for signs of wear, water damage, or warping. Early detection can enable repairs or timely replacements.

- Cleanliness: After use, clean the plywood surfaces to remove any concrete residues. This ensures it remains in good condition for future use.

- Moisture Control: Always keep the plywood stored in dry environments. If wet, allow it to dry properly before storage.

When to Replace Your Plywood

Even with the best maintenance practices, eventually, your formwork plywood will need to be replaced. Here are some signs announcing the end of its lifespan:

1. Visible Damage

Cracks, splits, and warping are significant indicators that your plywood may no longer provide reliable support. Replace damaged plies to prevent failure during construction.

2. Reduced Structural Integrity

If you find that your plywood is bending or losing its shape under the weight of concrete, it’s time for a replacement. Safety is paramount in construction, and compromised materials increase risk.

3. Decreased Usability

As formwork plywood ages, its reusability diminishes. If it can only withstand a single use without significant damage, investing in new plywood may be necessary.

The Future of Formwork Plywood

The construction industry is continuously evolving, with advancements in materials and techniques emerging regularly. The current trend leans toward sustainability, leading to innovations in plywood manufacturing. Expect to see:

- Eco-Friendly Options: A growing demand for environmentally friendly materials will encourage the development of eco-friendly plywood products that provide the same level of performance.

- Smart Plywood: With technological advancements, smart plywood that can sense stress, humidity, or temperature in real-time might become mainstream, allowing for better monitoring and maintenance.

Final Thoughts to Ponder

Choosing the right formwork plywood is crucial for your construction project. Understanding the factors that influence its lifespan allows for better decision-making and can lead to substantial cost savings. Whether you opt for moisture resistant plywood or film faced plywood, remember that proper usage, maintenance, and timely replacements are imperative to safety and project efficiency. By being proactive rather than reactive, you’ll optimize your materials and set the groundwork for a successful project.

Linked Product

HDO Basic 2S Formply

HDO Basic 2S Formply by Vinawood is a high-density overlay plywood designed for durability and repeated use in concrete forming applications. Made from 100% hardwood and featuring a resilient HDO coating, it offers resistance to abrasion, moisture, and chemicals. This product provides a smooth surface that maintains its quality over multiple uses, making it a practical choice for construction projects.

View Product